1.Ukubuka konke

Uma kuqhathaniswa nebhodi le-gypsum, ibhodi le-magnesium oxide liqinile futhi lihlala isikhathi eside, linikeza ukumelana nomlilo okuhle kakhulu, ukumelana nezinambuzane, ukumelana nesikhunta, nokumelana nokugqwala.Iphinde inikeze ukufakwa kahle komsindo, ukumelana nomthelela, kanye nezakhiwo zokuvikela.Ayishi, ayinabo ubuthi, inendawo eyamukelayo yokubopha, futhi ayinabo ubuthi obuyingozi obutholakala kwezinye izinto zokwakha.Ukwengeza, ibhodi ye-magnesium oxide ayisindi kodwa iqine ngokwedlulele, ivumela izinto ezisetshenziswayo ezizacile ukuthi zithathele ezijiyile ezinhlelweni eziningi.Ukumelana kwayo nomswakama okuhle kakhulu kunomthelela ekuphileni kwayo okude, njengoba kuboniswa yi-Great Wall yaseChina.

Ngaphezu kwalokho, ibhodi le-magnesium oxide kulula ukulicubungula futhi lingagawulwa, libholwe, limise okwe-router, lithole amaphuzu futhi lihlwithwe, libethelwe, futhi lipendwe.Ukusetshenziswa kwayo embonini yezokwakha kubanzi, kufaka phakathi izinto ezingashi ophahleni kanye nezindonga ezakhiweni ezahlukahlukene njengezakhiwo zamafulethi, amathiyetha, izikhumulo zezindiza, nezibhedlela.

Ibhodi le-Magnesium oxide alinamandla kuphela kodwa futhi lihambisana nemvelo.Ayiqukethe i-ammonia, i-formaldehyde, i-benzene, i-silica, noma i-asbestos, futhi iphephe ngokuphelele ukusetshenziswa komuntu.Njengomkhiqizo wemvelo osebenziseka kabusha ngokugcwele, ushiya i-carbon footprint encane futhi unomthelela ongemuhle kwezemvelo.

2.Inqubo Yokukhiqiza

Kubaluleke kakhulu ngamabhodi e-magnesium chloride lapho ama-ion e-chloride engeziwe angaba yinhlekelele.Ibhalansi engalungile phakathi kwe-magnesium oxide ne-magnesium chloride iholela kuma-ion e-chloride engeziwe, angase agibele phezu kwebhodi.Uketshezi olubolayo olwakheka, oluvame ukubizwa ngokuthi i-efflorescence, luphumela kulokho okwaziwa ngokuthi 'amabhodi okukhala.'Ngakho-ke, ukulawula ukuhlanzeka kanye nesilinganiso sezinto zokusetshenziswa phakathi nenqubo yokuhlanganisa kubalulekile ukuze kuqinisekiswe ubuqotho besakhiwo sebhodi futhi kuvinjwe i-efflorescence.

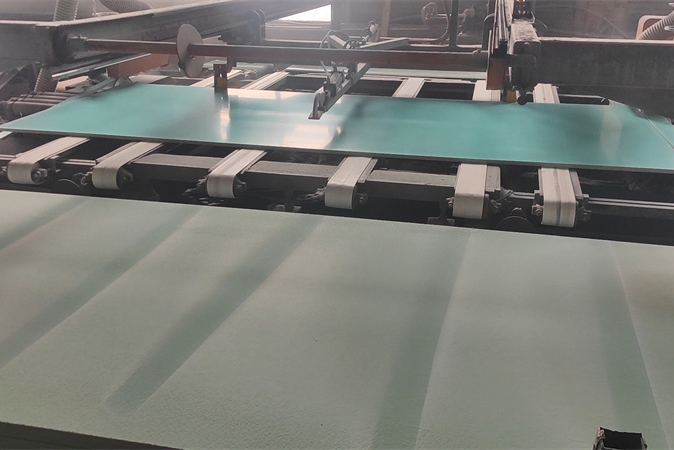

Uma izinto zokusetshenziswa sezixubene kahle, inqubo iqhubekela ekwakhekeni, lapho kusetshenziswa izingqimba ezine zemeshi ukuze kuqinisekiswe ukuqina okwanele.Futhi sihlanganisa uthuli lwezinkuni ukuze sithuthukise ukuqina kwebhodi ngokuqhubekayo.Izinto ezisetshenziswayo zihlukaniswa zibe izingqimba ezintathu kusetshenziswa izingqimba ezine zemeshi, zakha izikhala ezingokwezifiso njengoba kudingeka.Ngokuphawulekayo, lapho kukhiqizwa amabhodi ane-laminated, uhlangothi oluzobe lwenziwe nge-laminated lugxiliwe ukuze luthuthukise ukunamathela kwefilimu yokuhlobisa futhi luqinisekise ukuthi aluguquki ngaphansi kokucindezeleka okuqinile okuvela endaweni e-laminating.

Ukulungiswa kwefomula kungenziwa ngokusekelwe ekucacisweni kweklayenti ukuze kuzuzwe izilinganiso ezihlukahlukene ze-molar, ikakhulukazi uma ibhodi lihanjiswa ekamelweni lokuphulukisa.Isikhathi esichithwa endaweni yokwelapha sibalulekile.Uma kungelapheki kahle, amabhodi angase ashise kakhulu, alimaze isikhunta noma abangele amabhodi ukuba aguqule.Ngakolunye uhlangothi, uma amabhodi ebanda kakhulu, umswakama odingekayo ungase ungahwamuki ngesikhathi, kube nzima ukudiliza nokwandisa isikhathi nezindleko zabasebenzi.Kungase ngisho kubangele ukuthi ibhodi ichithwe uma umswakama ungakwazi ukususwa ngokwanele.

Imboni yethu ingenye yezimbalwa ezinokuqapha izinga lokushisa emagumbini okwelapha.Singakwazi ukuqapha izinga lokushisa ngesikhathi sangempela ngamadivaysi eselula futhi sithole izexwayiso uma kukhona ukungezwani, okuvumela abasebenzi bethu ukuthi balungise izimo ngokushesha.Ngemva kokuphuma ekamelweni lokuphulukisa, amabhodi athola cishe isonto lokuphulukiswa kwemvelo.Lesi sigaba sibalulekile ukuhwamulisa noma yimuphi umswakama osele.Emabhodini ashubile, kugcinwa izikhala phakathi kwamabhodi ukuze kuthuthukiswe ukuhwamuka komswakama.Uma isikhathi sokuphulukisa singanele futhi amabhodi athunyelwa ngaphambi kwesikhathi kakhulu, noma yikuphi umswakama osele ovalelwe ngenxa yokuxhumana ngaphambi kwesikhathi phakathi kwamabhodi kungaholela ezinkingeni ezibalulekile uma amabhodi efakiwe.Ngaphambi kokuthunyelwa, siqinisekisa ukuthi umswakama omningi odingekayo uhwamukile, ovumela ukufakwa okungenakukhathazeka.

Lokhu okuqukethwe okuthuthukisiwe kunikeza ukubheka okuphelele kwenqubo yokucophelela ehilelekile ekukhiqizeni amabhodi ekhwalithi ephezulu e-magnesium oxide, okugcizelela ukubaluleka kokunemba ekuphatheni nasekuphulukiseni izinto.

3.Izinzuzo

4.Ezemvelo kanye Nokusimama

I-Low Carbon Footprint:

Ibhodi le-Gooban MgO wuhlobo olusha lwempahla yejeli enekhabhoni ephansi.Inciphisa kakhulu ukusetshenziswa kwamandla okuphelele kanye nokukhishwa kwekhabhoni kusukela ekukhishweni kwezinto ezingavuthiwe kuya ekukhiqizeni nasekuthuthweni uma kuqhathaniswa nezinto ezivamile ezingashi njenge-gypsum nosimende wase-Portland.

Mayelana nezici zokukhishwa kwekhabhoni, usimende wendabuko ukhipha ama-740 kg CO2eq/t, i-gypsum yemvelo ikhipha ama-65 kg CO2eq/t, kanti ibhodi ye-Gooban MgO ingu-70 kg CO2eq/t kuphela.

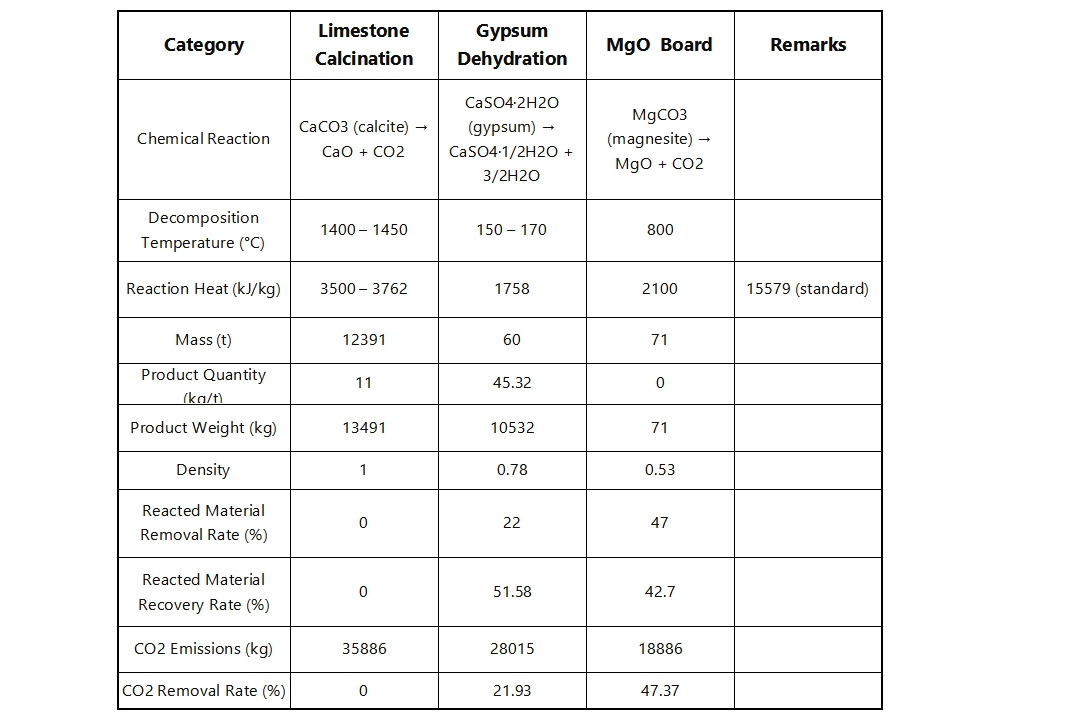

Nansi idatha ethile yokuqhathanisa amandla nekhabhoni:

- Bheka ithebula ukuze uthole imininingwane yezinqubo zokubunjwa, amazinga okushisa okubala, ukusetshenziswa kwamandla, njll.

- Uma kuqhathaniswa nosimende wase-Portland, ibhodi le-Gooban MgO lidla cishe ingxenye yamandla futhi likhipha i-CO2 encane kakhulu.

5.Uhlelo lokusebenza

Izicelo Ezibanzi ZeMagnesium Oxide Boards

I-Magnesium Oxide Boards (i-MagPanel® MgO) iya ngokuya igqama embonini yezokwakha, ikakhulukazi uma kubhekwa izinselelo zokushoda kwabasebenzi abanamakhono kanye nezindleko zabasebenzi ezikhuphukayo.Le nto yokwakha esebenza kahle, enemisebenzi eminingi ithandwa ukwakhiwa kwesimanje ngenxa yokusebenza kahle kwayo okubalulekile nokonga izindleko.

1. Izinhlelo zokusebenza zasendlini:

- Ama-partitions kanye nophahla:Amabhodi e-MgO anikeza ukuvala umsindo okuhle kakhulu kanye nokumelana nomlilo, okuwenza alungele ukudala izindawo zokuhlala eziphephile, ezithule kanye nokusebenza.Imvelo yabo engasindi nayo yenza ukufakwa kusheshe futhi kunciphise umthwalo wesakhiwo.

- I-Underlay yaphansi:Njenge-underlay ezinhlelweni ze-flooring, amabhodi e-MgO ahlinzeka ngomsindo owengeziwe nokufakwa kwe-thermal, athuthukisa umthamo wokuthwala umthwalo nokuzinza kwephansi, futhi andise ubude besikhathi sawo sokuphila.

- Amaphaneli okuhlobisa:Amabhodi e-MgO angelashwa ngokuqedwa okuhlukahlukene, okuhlanganisa ukuthungwa ngokhuni namatshe noma upende, ukuhlanganisa ukusebenza kanye nobuhle ukuze kuhlangatshezwane nezidingo ezihlukahlukene zemiklamo yangaphakathi.